The Importance of MDMT in Preventing Brittle Fracture Failures

The rules of UCS-66 are some of the most important and yet most misunderstood provisions of the ASME Code. Because of its importance, minimum design metal temperature (MDMT) is one of just a few critical parameters stamped onto vessel nameplates. The rules of UCS-66 guard against vessel failure by brittle fracture, a low probability high consequence event. Brittle fracture failures exhibit “break before leak” behavior and can be catastrophic in that they entail high risks and occur without warning. Carbon steel pressure vessels are most susceptible to brittle fracture during start up, shut down, hydro test (test water that is too cold) and rapid depressurization (auto-refrigeration). Given the consequences of this type of failure, all relevant factors listed in UCS-66 need to be properly addressed. These include consideration of the coldest temperature expected, metallurgy, material thickness, post weld heat treatment, impact testing, applied stress and weld pass size.

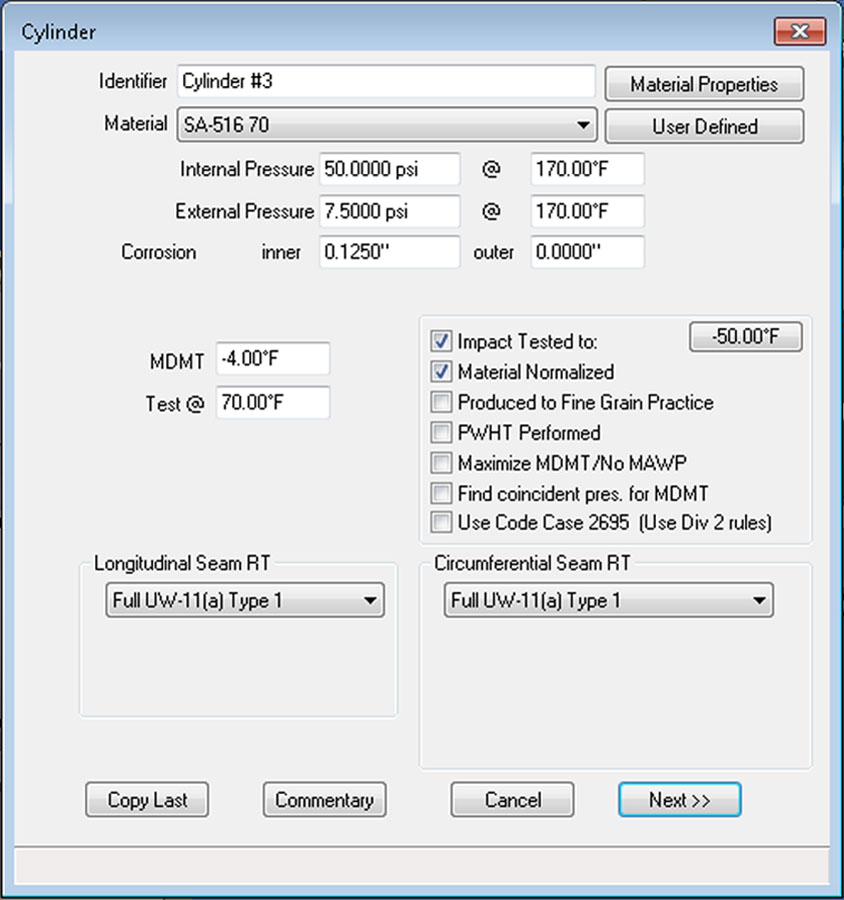

How COMPRESS Determines MDMT

COMPRESS assists the vessel designer by automatically finding the coldest impact test exempt MDMT allowed by Code. If this rated MDMT is warmer than the required MDMT, the designer is alerted and the limiting component(s) highlighted. At this point the designer can either change one of the component’s input variables or specify impact testing be performed. As impact testing is expensive, it is usually called for only when it is a Code or local jurisdictional (CSA) requirement. COMPRESS automatically:

A Brief UCS-66 Technical Background

It is widely acknowledged that it is impractical to build equipment that does not contain at least some flaws. In the discussion above, it was also stated that UCS-66 considers temperature, metallurgy, material thickness, post weld heat treatment, applied stress and weld pass size. Roughly speaking, UCS-66 takes these factors in combination with an assumed critical flaw size to arrive at its MDMT ratings. Let’s take a look at the factors involved and hopefully shed a little light on why they are used and how they affect the toughness of carbon and low alloy steels.

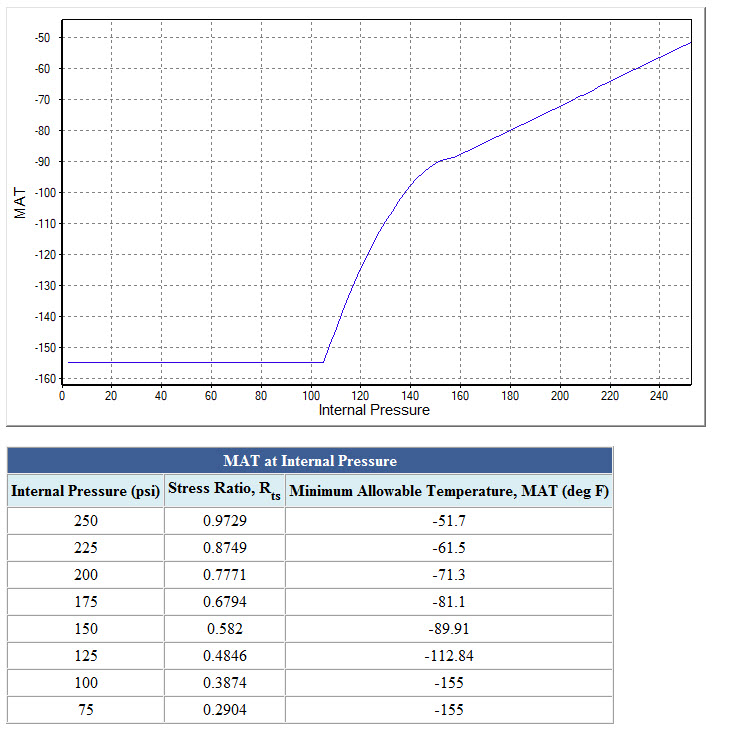

MDMT Ratings and Vessels Built Before 1987

UCS-66 Code rules apply to new construction. But what if the vessels in your plant were fabricated before 1987, the year the MDMT rules of UCS-66 were put in place? This is where our API 579-1/ASME FFS-1 Fitness-For-Service software, INSPECT, comes into the picture. INSPECT includes API 579-1 Part 3 brittle fracture assessments and the ability to produce Minimum Allowable Temperature (MAT) curves . INSPECT’s MAT feature automatically runs Part 3 assessments over a range of pressures to simplify and speed up the creation of equipment integrity operating windows.

+1 (941) 927-2670 | sales@codeware.com