INSPECT’s Inspection Data Monitoring System (IDMS)

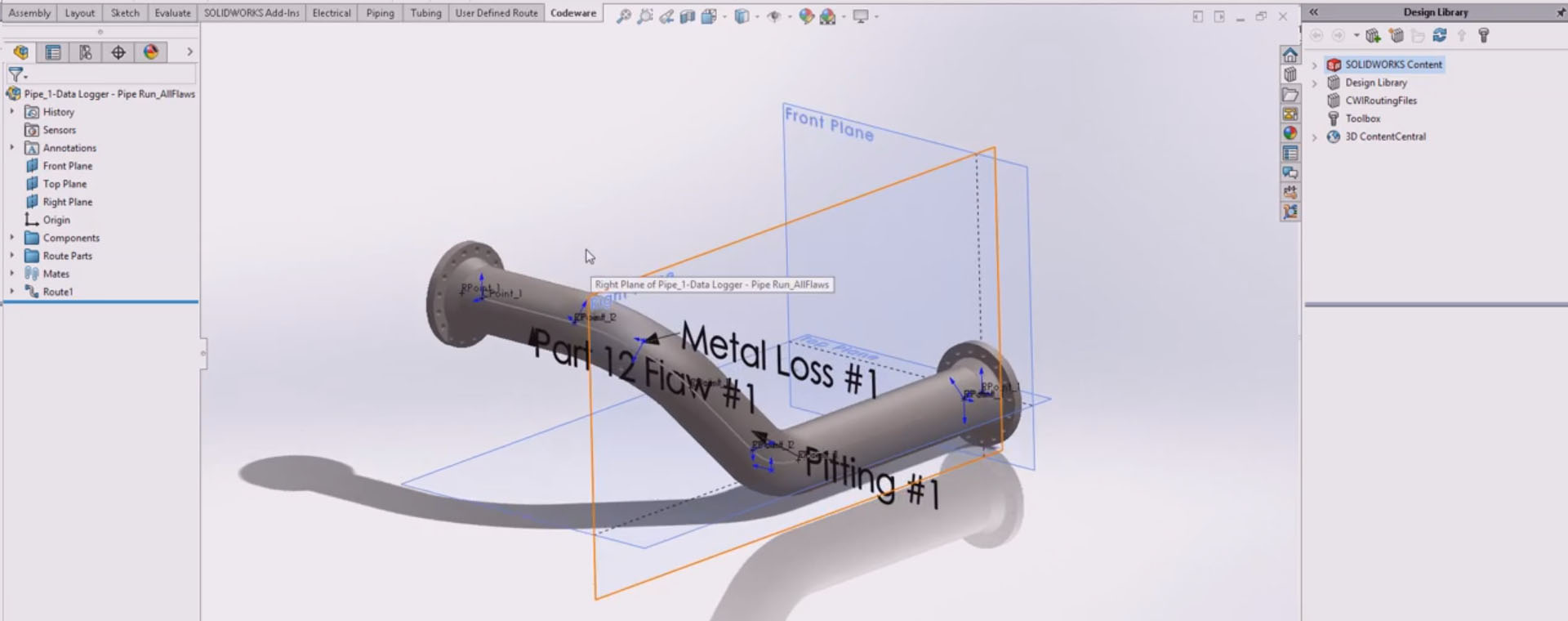

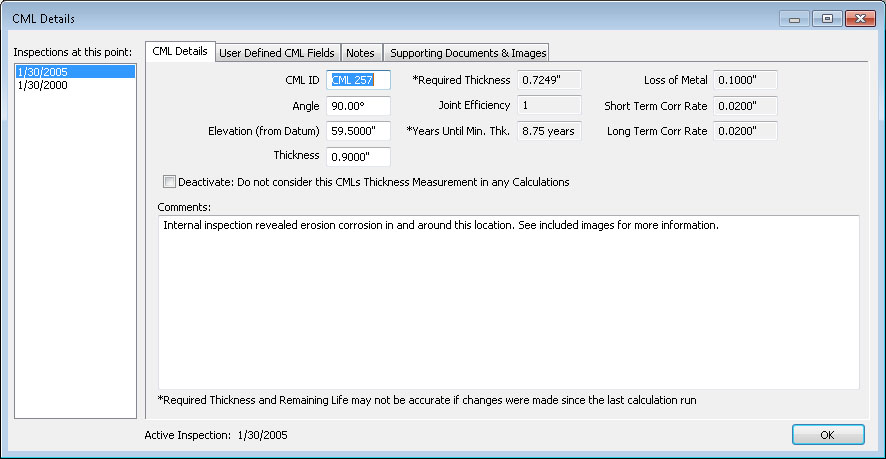

INSPECT’s built-in 3D inspection data management system has the unique ability to show condition monitoring locations (CML’s) and API 579-1 flaws directly on pressure equipment models. Another key advantage is its ability to easily customize data tracking to meet your needs. Inspection comments and documents, including images, can be quickly attached to any CML. INSPECT provides a summary that highlights which CML governs and which CML’s contain additional information. It also provides options to flag data anomalies and define how they are shown. But perhaps the greatest benefit of all is that INSPECT’s rigorous tmin calculations are tightly integrated with the IDMS. This saves time and reduces input errors because there is no longer a need to do tmin calculations in a separate program and then manually enter them into your IDMS.

INSPECT’s integration of ASME and API Codes with your inspections adds value to your data by making it easy to see what affect changes to process variables such as pressure or temperature will have on inspection schedules and remaining life. In addition, INSPECT’s IDMS can track GPS positions of fixed equipment and any associated API 579 flaws. This saves time and reduces errors by helping personnel quickly and accurately locate equipment and inspection locations within your facility.

Easy CML Data Customization

Easy CML Data Customization

IDMS Administrative Controls

IDMS Administrative Controls

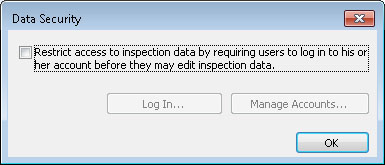

Administrative access controls are critical to the integrity of the data stored in an inspection data management system. INSPECT’s data security feature provides tools which enable system administrators the ability to grant individuals different data access permissions as appropriate. The administrative controls provided include the ability to create new users, assign passwords and set the following user privileges:

INSPECT Featured Capabilities

Find Out More