Hydrogen Induced Cracking (HIC) and Hydrogen Blisters

As their names suggest, Hydrogen Induced Cracking (HIC) and Hydrogen Blisters are flaws caused by exposing carbon steel equipment to hydrogen. Hydrogen can find its way into material imperfections and form expanding internal pockets which can lead to HIC or Blister damage.

API 579-1, Part 7 assessments of Hydrogen Induced Cracking and Hydrogen Blisters are both included in INSPECT. Level 1 and 2 flaw assessments can be performed. As is the case with all flaw types in INSPECT, multiple HICs or Blisters can be specified on one component. This increases productivity and ensures factors including supplemental loads, nearby flaws and structural discontinuities are taken into account.

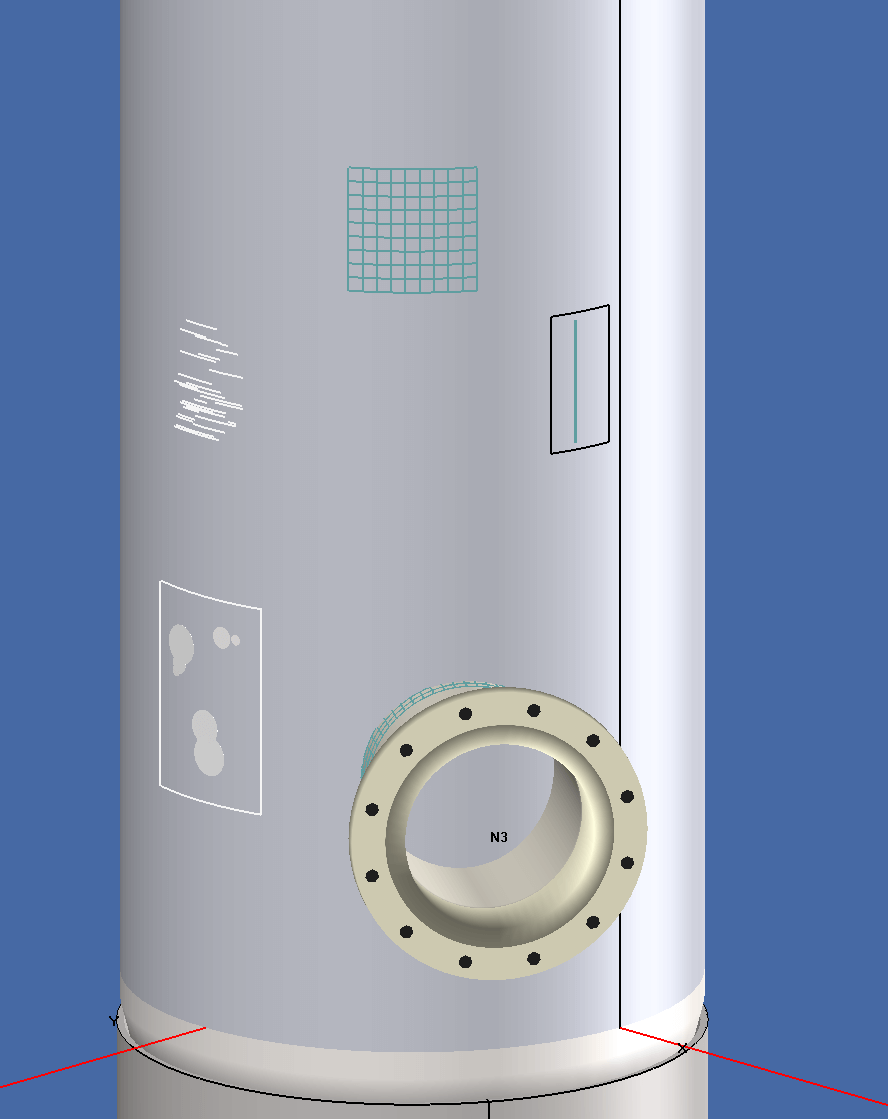

Level 1 Assessments

Part 7 Level 1 screening assessments require only a minimum amount of data entry and so can be quickly performed. Interactive calculation results, available from within the dialog, help to support faster decision making . In addition, users can easily adjust inputs and see up-to-date results based on “What-if” scenarios.

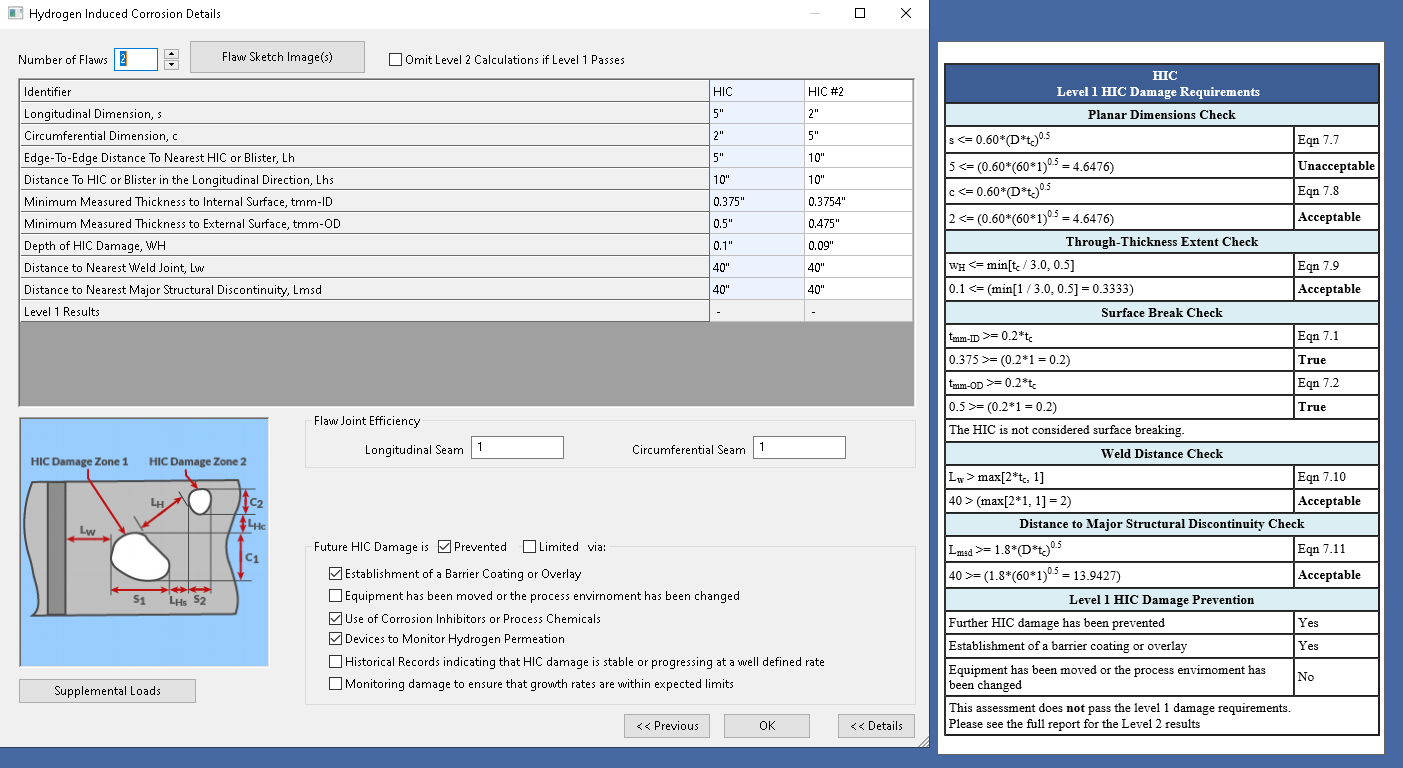

Level 2 Assessments (HIC)

Part 7 Level 2 assessments can be automatically performed by INSPECT. To save time and shorten the reports, you have the option of only running Level 1 if the flaw passes Level 1. As per API 579-1, Part 7 Level 2 assessments follow the Part 5 and 9 rules for HICs and Part 5 for Blisters.

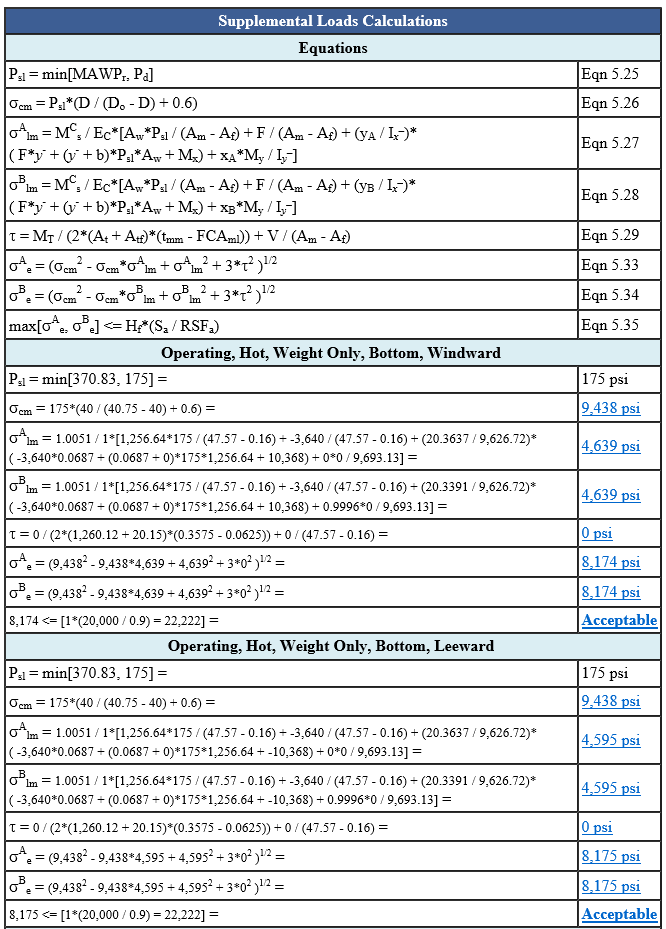

Detailed API 579-1 Part 7 Calculations and Reports

As is the case for all flaw types, INSPECT generates detailed reports that show all supporting API 579-1 and ASME calculations. Supplemental Loads will automatically be considered in the assessment as applicable as well. These engineering reports provide the documentation needed to support your run, repair or replace decisions.

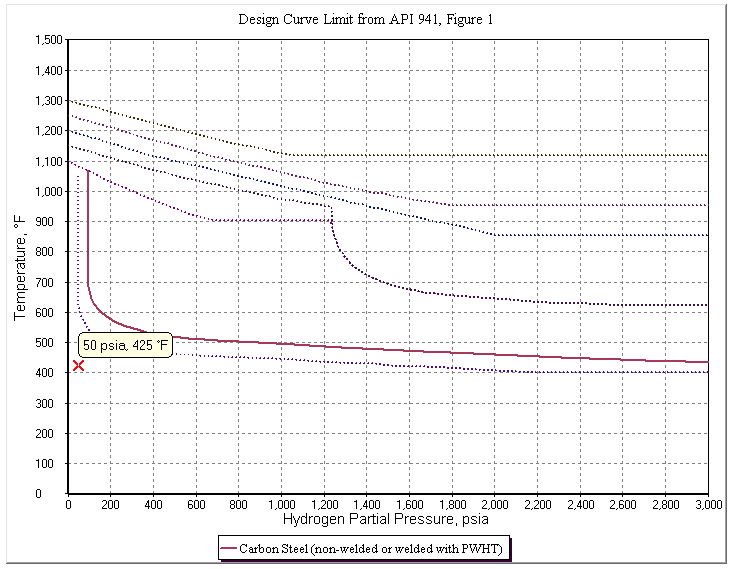

Another convenient feature is INSPECT’s optional API 941 (Nelson Curve) temperature check. It is used to determine if the Part 7 assessment procedure is valid for use at temperatures exceeding 400 degrees F (204 degrees C).

+1 (941) 927-2670 | sales@codeware.com