Conventional and Half Pipe Jackets in COMPRESS

COMPRESS 2022 Build 8200 adds the ability to design both conventional and half pipe jacketed vessels as a standard feature. Conventional jackets create a zone of external pressure on the internal vessel shell and are typically designed using the rules of ASME UG-28 and Appendix 9. Because the interior shell is subject to external pressure, conventional jackets have historically been used in smaller, lower pressure\temperature applications. Using COMPRESS to design conventional jackets to ASME VIII-2 (Division 2) can result in thinner inner shells. This is accomplished by taking advantage of both the higher allowable stresses and more accurate external pressure rules provided by Division 2.

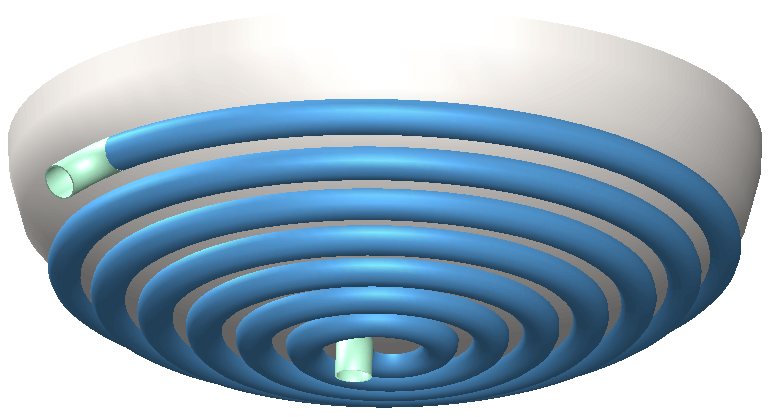

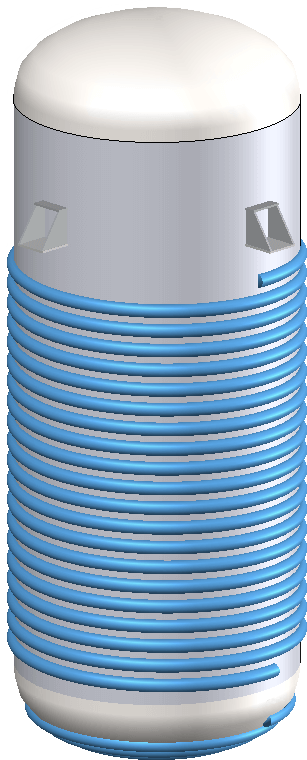

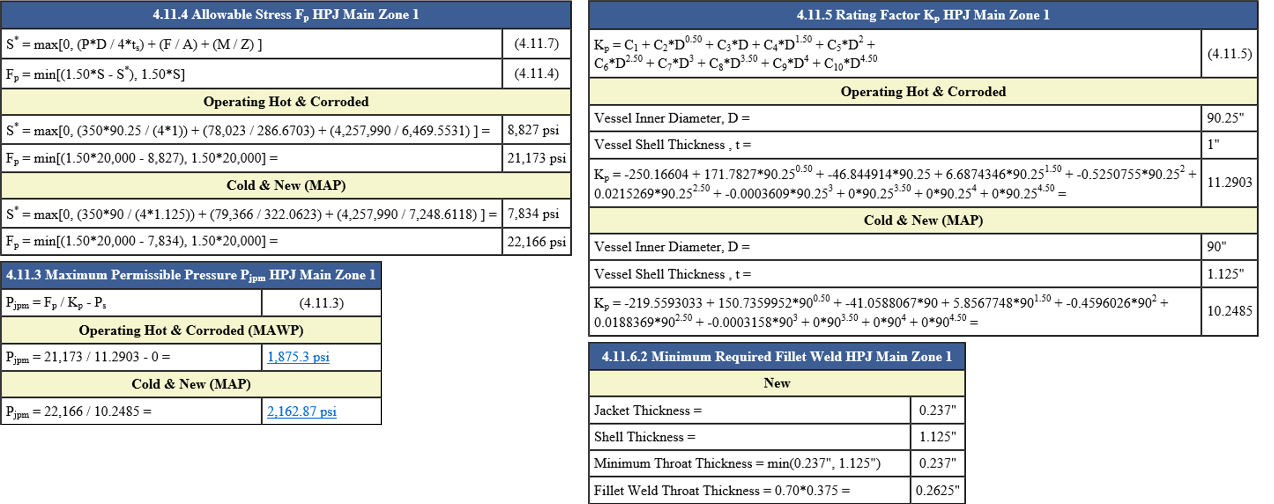

For larger diameter or higher pressure\temperature applications, half pipe jackets usually provide a more economical construction. COMPRESS can design half pipe jackets using the rules found in ASME VIII-1, Appendix EE and ASME VIII-2, Part 4.11. The higher allowable stresses provided by COMPRESS Division 2 half pipe jacket designs can result in material weight savings and more economical jacketed vessels.

Complete, Easy to Follow Half Pipe Jacket Design Reports

Complete, Easy to Follow Half Pipe Jacket Design Reports

COMPRESS features interactive data input and easy to read, collapsible reports. These abilities make designing conventional and half pipe jackets to Division 1 or Division 2 fast and easy.

Conventional Jacket Types 1 and 2

Conventional Jacket Types 1 and 2

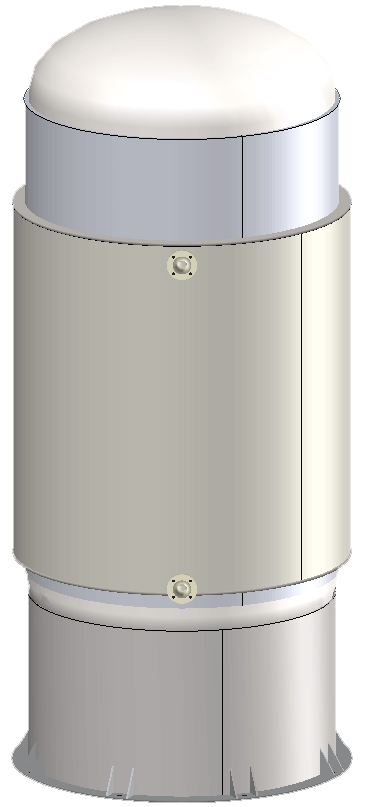

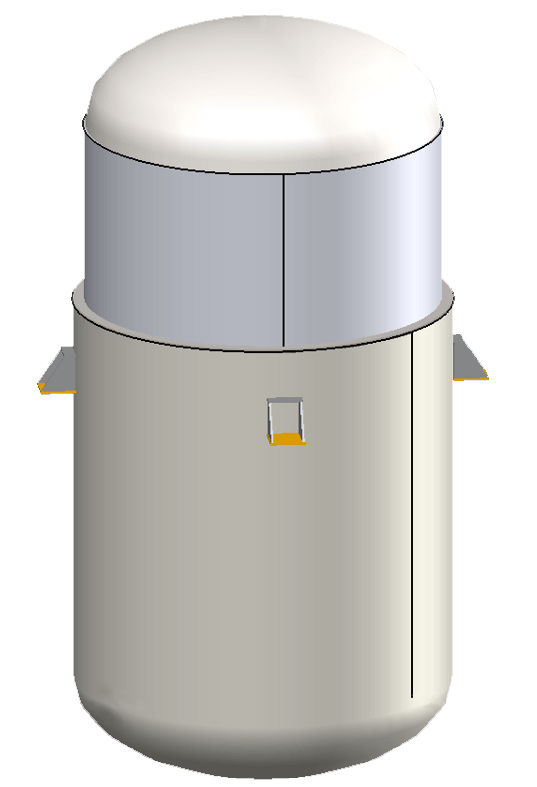

COMPRESS includes the ability to design conventional, Type 1 and Type 2 jackets. Nozzles may placed on the outer or inner shells. If placed on the inner shell, COMPRESS offers the various jacket penetration options as shown in Figure 9-6 from Appendix 9.