Shopfloor

ASME IX and AWS Welding Procedure Software

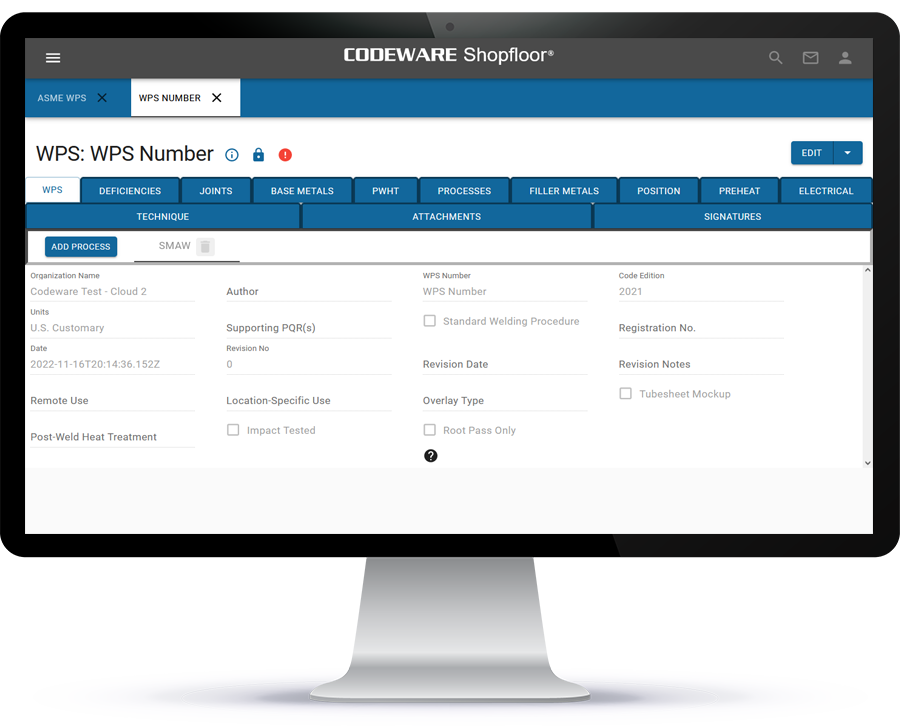

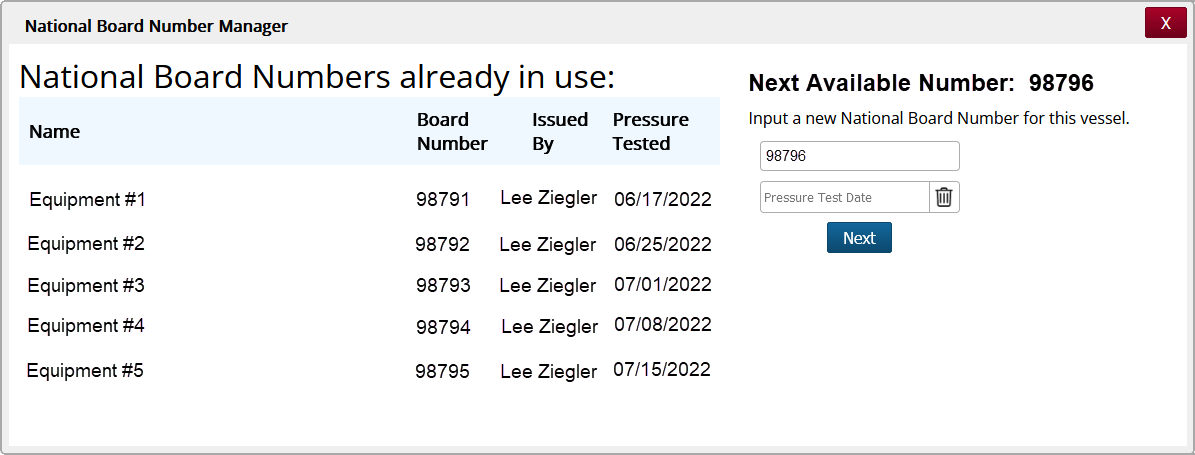

Shopfloor is a cloud based welding management software system. With Shopfloor, all your QC documentation is available from within one platform. Shopfloor helps prevent issues like welding procedure duplication and welder qualifications expiring because of a lack of advance notice. Welding Code checks, Shop Travelers, and SAP integration boost your productivity as well.

Shopfloor provides easy access to your welding documents from any internet connected device. Because Shopfloor is cloud-based, your valuable information is protected from threats like hard disk crashes and ransomware. It does not require Microsoft Remote Desktop to function. This simplifies software implementation and improves system performance and reliability.

ASME IX and AWS Welding Procedure Management Simplified

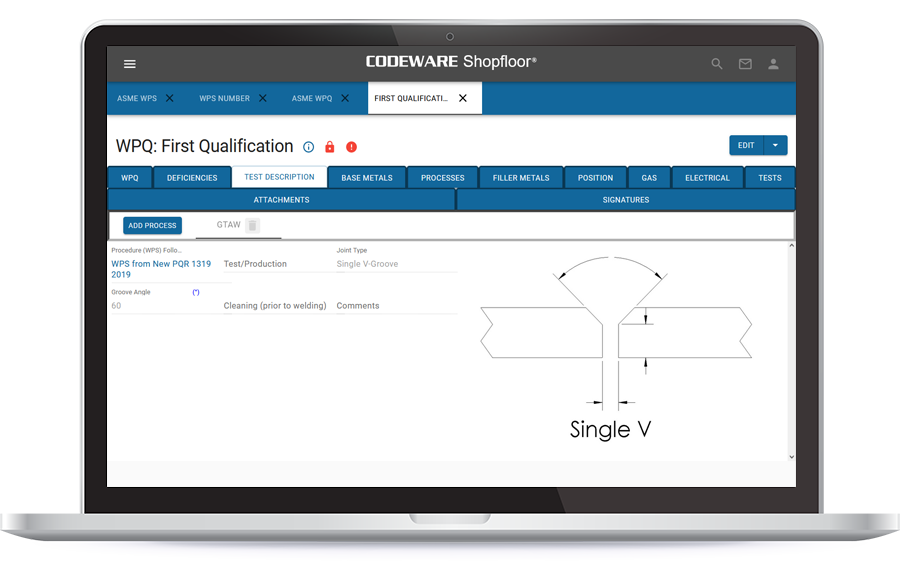

Shopfloor is easy to learn and simple to use. Shopfloor’s powerful search functionality makes finding what you’re looking for simple and quick. It enables you to organize jobs by location, create the required welding procedures and forms, and track welder continuity.

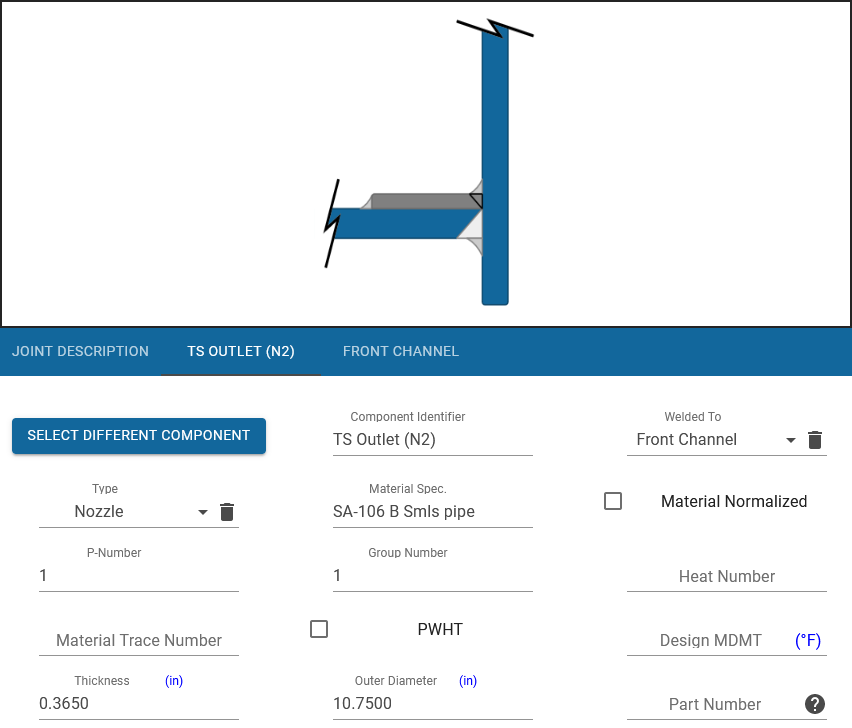

Shopfloor also integrates with COMPRESS and INSPECT. It quickly determines if additional welding procedures or welder qualifications are needed and assists in selecting the right procedures and welders for the job. Shopfloor’s one-click document deliverables feature gathers everything up in one neat package for submission at project completion.

ASME IX and AWS Welding Procedure Setup Service

Our setup service takes the hassle out of upgrading your legacy welding system to Shopfloor. This process involves scanning your existing paper forms, removing duplicates, and using Shopfloor’s built-in checks for ASME IX and AWS Code compliance. We note the Code issues and duplicates found and input the forms into Shopfloor making them available for your immediate use.

To help get you up and running quickly all Shopfloor subscriptions also include software training. Whether you are moving from a paper based system or transitioning from another welding procedure software our implementation staff can assist you. We invite you to contact a member of our sales team to discuss your needs and get more information.

Recent Shopfloor Enhancements

Find Out More