Let’s face it – software packages like COMPRESS exist to increase productivity and save valuable Engineering hours. There are many complex items involved when selecting a pressure vessel design software so the purpose here is to break it down into a more manageable task. In our estimation, there are two general areas to consider. First, how complete are the calculations performed and second, is it a good piece of software or is it awkward to use? The first consideration deals primarily with Mechanical Engineering while the second is more of a Computer Science and user interface discussion. With that being said, here goes:

Does the Software Perform the Calculations You Need and Expect?

All ASME® calculation software offerings claim the same thing: “we perform ASME calculations”. This makes it hard to sort out the differences between the various packages because it’s not always clear which Code provisions have been automated and which rely on manual input of the required parameters. Here are some common productivity killing things to watch out for:

How quickly can you find out if a component is passing (or failing) Code compliance? Do you waste a lot of time searching the report to see? COMPRESS shows Code compliance interactively as components are created.

Do you input UCS-66 data like material chart assignments or UCS-68(c) exemptions manually or does the software figure it out for you? UCS-66 rules are complicated so this comes up a lot with in-house spreadsheets. A surprising number of commercial programs don’t get this right either.

Are you required to manually determine and input external pressure design lengths or does the software provide them for you?

Do you have to manually calculate and input chord opening lengths for non-radial nozzles or does the software do it for you?

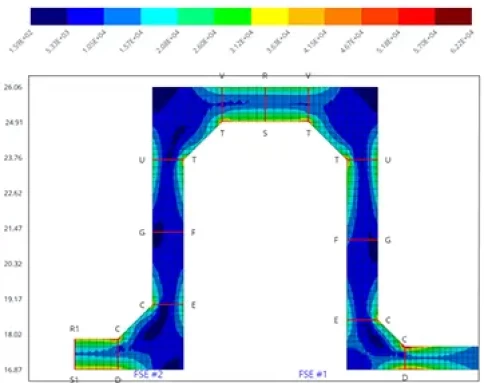

Is the money saving

ASME Appendix 46 included or do you have to do these designs by hand?

Is liquid static head considered by entering a pressure you calculate or does the software do it for you based on a stated liquid level? Most process vessels contain liquids and this calculation is mandatory per UG-98(a).

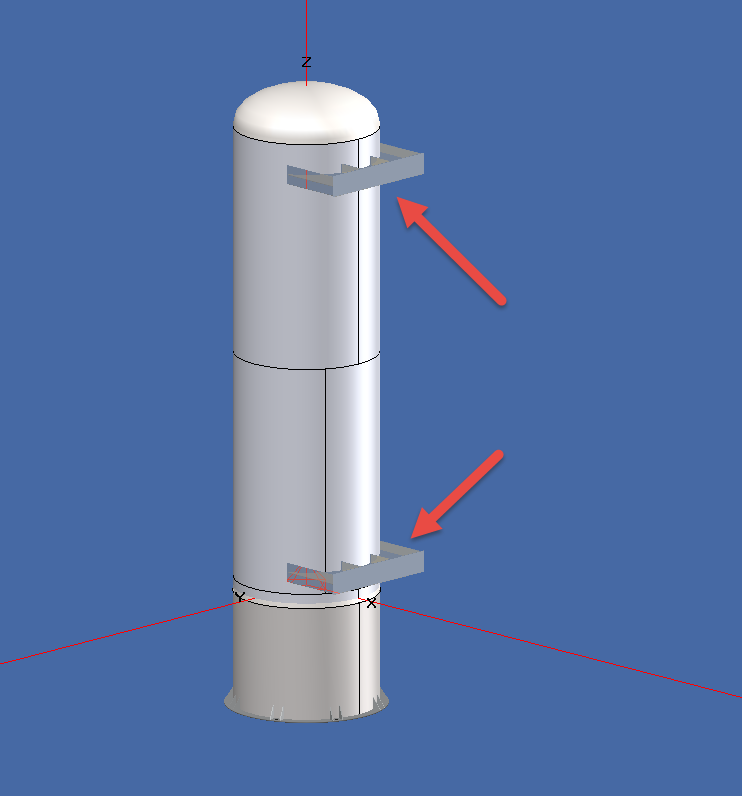

Every vertical vessel needs to be transported and this requires the design of shipping saddles. Does the software include this feature or are you going to have to do this calculation by hand?

Can vessel material schemes be set up and re-used or do you need to select materials for each component every time?

Do you need to go back and check every component’s thickness after changes are made or does the software offer a true

design mode?

Limited implementations of Part 4 of

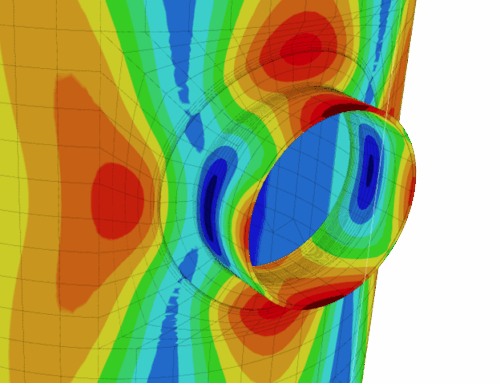

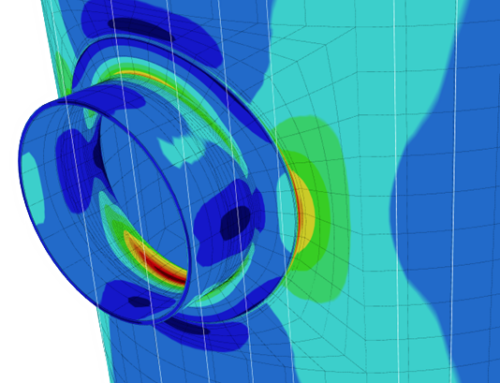

Division 2. This may be worse than no Division 2 implementation at all. Can the software perform

pressure vessel fatigue evaluations?

Can the software perform automatic deflection calculations for tall towers? This is a common requirement as vessel owners often require wind induced tower deflections be limited to a set amount.

Are a wide range of vessel supports included? In addition to skirts and saddles, can it handle legs and lugs?

Is the Software a Modern, Easy to Use Program?

All software vendors claim that their user interface is “easy to use”. Unfortunately, many features that are commonly assumed to be part of a modern software application are simply not present in competing products. Here are eleven time wasters to look out for:

Can the software create Manufacturer’s Data Reports from completed designs? Is this accomplished from within one program or does it require a separate “module” requiring more data entry from you?

Does the software have an undo\redo feature? COMPRESS does.

Do you need to install, learn and maintain two separate programs, one for “components” and one for “complete vessels”? Why can’t one consistent user interface, design report and file format suffice?

Do you have to waste time generating design reports by manually pasting them together in a word processor like Word®? This can happen if the calculations you need are split between more than one program.

Can you easily customize your report’s cover page?

There are many nozzles on a typical vessel so how they are handled really matters. For example, can nozzles be copied and pasted between vessels by dragging and dropping them into position?

Can the software easily handle common purchased items like B16.9 elbows?

Is your data locked up in a proprietary file format or can it be easily exported into other programs like

Inventor®, SOLIDWORKS® or

Excel®?

Making changes to designs happens all the time. For example, can you change head types without having to re-enter all the attached nozzles?

Is there a seamless upgrade path available if you eventually need more capability? Do you think you might require

FFS or

Welding?

How good is their support service? Can you get timely, accurate answers to your questions?

The previous lists are just part of the story. To get a more complete picture of how COMPRESS can save your company time and money we invite you to contact us today by clicking on the button below.