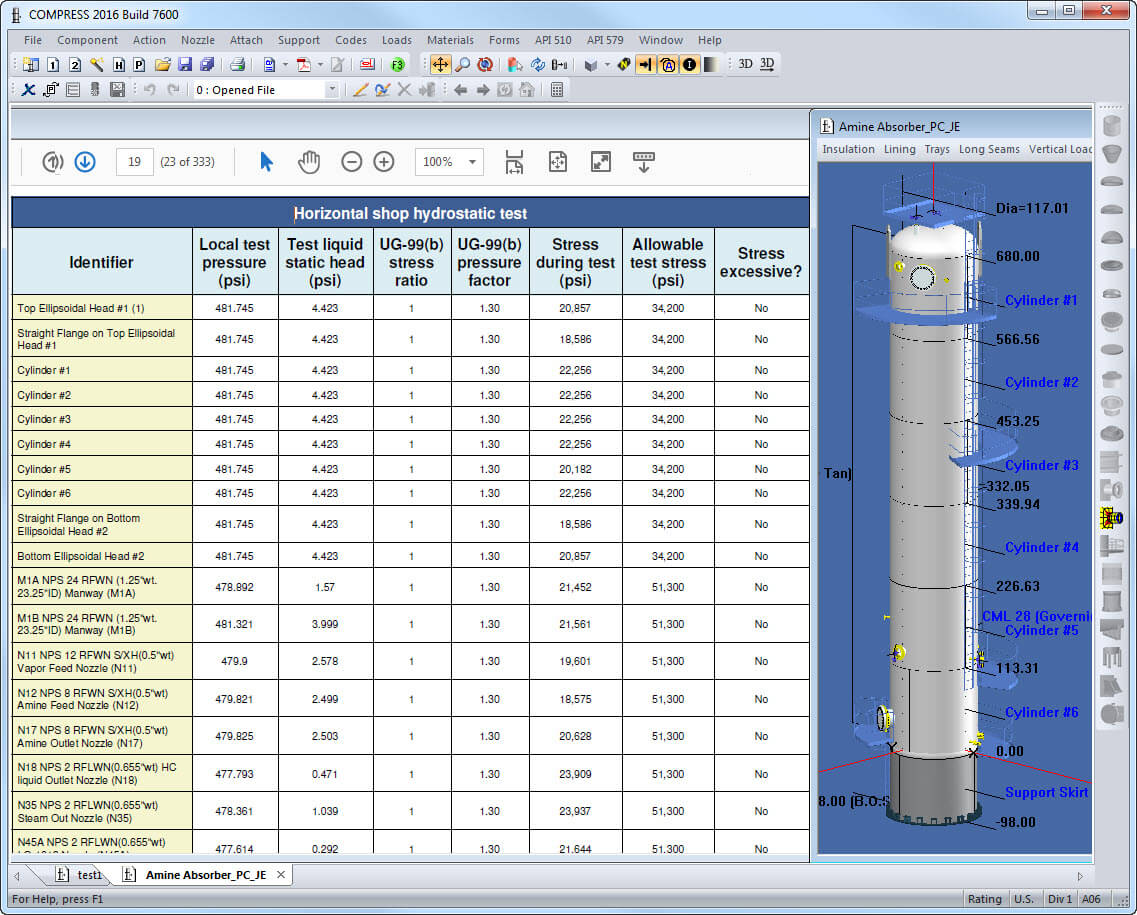

Check ASME Vessel & Exchanger Stresses Before Testing

The ASME Code requires that all vessels undergo hydro (or pneumatic) testing following fabrication and before Code stamping. As this test provides mechanical stress relief it may be thought of as the final step in the fabrication process. The hydro test is an effective way to screen for design, material and fabrication deficiencies as well as to prove the structural integrity of the equipment.

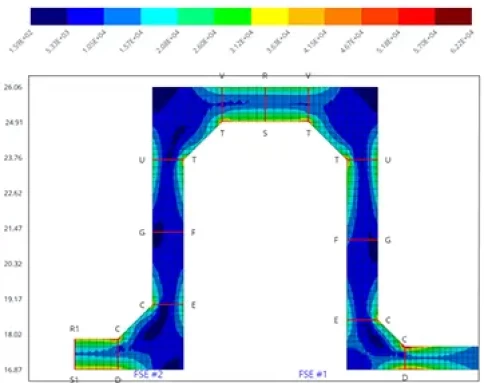

However, this raises the question – what constitutes a hydro test “design deficiency”? Although ASME Section VIII-1 does not prescribe a test stress limit, vessels that undergo “objectionable distortion” during testing may be rejected by your AI. The COMPRESS Hydro Test Feature assists you by:

Is the Hydro Test Report a standard COMPRESS feature?

How do I view it?

How do I view it?

Yes, the Hydro Test Report is available to all COMPRESS users. To prepare your report:

- Design your vessel or exchanger.

- Select your test basis in Set Mode Options > Defaults > Testing.

- Press F3 to generate the Code calculations. Click "Hydrostatic Test" on the left to view the report.

- Check for overstressed components and revise your design as necessary. To speed your review, COMPRESS also includes any overstressed components in the Deficiency Report.

Criteria for Limiting Hydro Test Stress in COMPRESS

ASME Section VIII Division 1 does not require stresses to be limited during hydrostatic test. COMPRESS provides the option to remove the test stress calculation. This is specified on the Testing tab of the Set Mode Options dialog. To remove the test stress calculations, uncheck the “Calculate hydrotest stress” option.

The allowable stresses for the test condition are established as follows:

This approach leads to the case where the allowable stresses will be different for nozzles and shells of the same material. This is because only (1) above is used for the shell and both (1) and (2) are applicable for the nozzle. For nozzles, the yield stress is taken as that of the parent component.

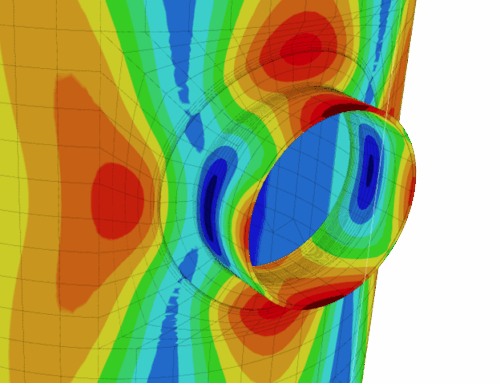

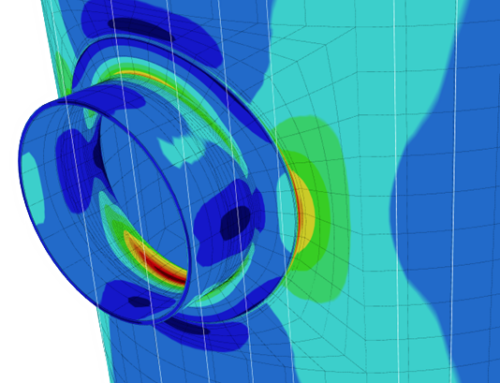

The determination of stresses in the shell at the nozzle opening are found using the method in Division 2, Part 4.5. COMPRESS uses Part 4.5 as it provides a basis to determine the local stress in the shell at the nozzle opening.

For further information, please see the Hydro Test section in our Support Center.

If you don’t have software that performs hydro test calculations, it’s time to explore the benefits of COMPRESS. Find out more by emailing sales@codeware.com or calling (941) 927-2670.

+1 (941) 927-2670 | sales@codeware.com