Codeware On-Demand Webinars & Tutorials

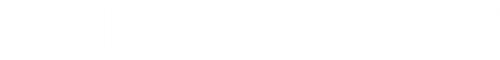

Multiple Pressure Chamber Stacked Vessel Design

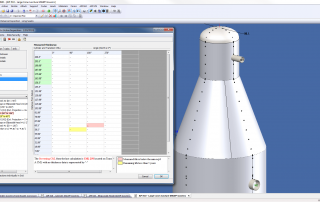

Having trouble viewing this video?Download video (.mov 10MB) Stacked Vessel Design Using COMPRESS Certain industrial processes require pressure vessels to be built with multiple chambers operating under different design conditions. COMPRESS and INSPECT both support multiple pressure chamber, stacked vessel designs. Benefits of using this feature include: Individual pressures, temperatures, materials, corrosion allowances etc. can be specified for each pressure [...]

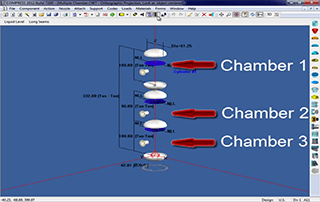

Import HTRI® Files Into COMPRESS or INSPECT

The Codeware HTRI interface COMPRESS and INSPECT offer a bi-directional interface with HTRI’s Xchanger Suite Xist®. This feature saves time and enhances collaboration between Mechanical and Thermal Designers. The HTRI interface is included at no additional charge with INSPECT and is provided with the COMPRESS Heat Exchanger Option. Xchanger Suite Xist users can access shell and tube heat exchanger (Xist) files [...]

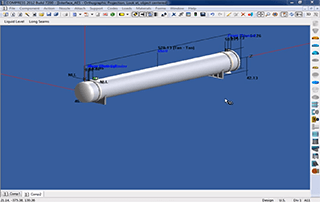

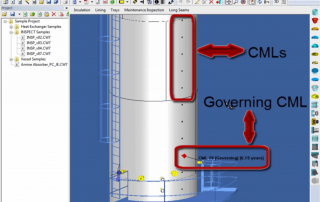

Vessel Data Charts and Process Loops

The INSPECT project feature allows equipment to be grouped and managed as process loops. This video shows how INSPECT can create custom vessel data charts that summarize a process loop's governing condition monitoring location (CML), remaining life and required inspection date. Having trouble viewing this video? Download video (.mov 19MB)

Condition Monitoring Location (CML) Placement

Having trouble viewing this video? Download video (.mov 34MB) This video explains how to add thickness survey data to an INSPECT (or COMPRESS) model. Placing condition monitoring locations (CML) and transferring thickness measurements from other software is discussed.

Introducing INSPECT – API 510 in 3D

Codeware is pleased to introduce INSPECT, software for mechanical integrity analysis of ASME VIII-1 equipment. Unlike other mechanical integrity software, INSPECT performs complete ASME calculations. INSPECT also records thickness surveys, shows condition monitoring locations (CMLs) and generates full reports. Having trouble viewing this video? Download video (.mov 37MB) [...]

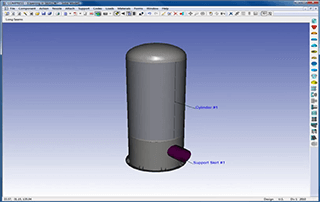

Openings in Support Skirts

Support Skirt Openings Piping connections to vertical vessels often require additional piping and an opening cut out of the support skirt. COMPRESS includes the ability to specify and check the adequacy of this commonly encountered design detail. Circular pipe sleeves, internal projections, tilt angles, and skirt reinforcing pads can be considered. The ability to add pipe elbows, reducers, and piping that [...]

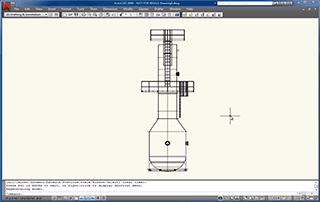

Import COMPRESS Files Into AutoCAD

See how to import COMPRESS 3D solid model files into AutoCAD®. The COMPRESS solid model export feature reduces the data entry needed to create pressure vessels within your drawing software. Having trouble viewing this video? Download video (.mov 14MB)

Why Perform UG-99 Hydrotest Stress Calculations?

ASME UG-99 Hydrostatic Test Stress Calculations ASME Code paragraph UG-99 requires that all vessels undergo hydrostatic (or pneumatic) testing before Code stamping. As this test provides mechanical stress relief it may be thought of as the final step in the fabrication process. The UG-99 hydrostatic test is an effective way to screen for design, material and fabrication deficiencies as well as to [...]

Why Specify Pressure Vessel Weld Seams?

Having trouble viewing this video? Download video (.wmv 4MB) View in Alternate Format The Advantages of Locating Pressure Vessel Weld Seams Although not required to perform basic (theoretical) ASME calculations, specifying weld seam locations when designing pressure vessels provides a number of practical advantages: Tall towers often require greater thicknesses near the bottom [...]

Import COMPRESS Files Into AutoCAD Plant 3D

See how to import COMPRESS 3D solid model files into AutoCAD Plant 3D. The COMPRESS solid model export feature saves time by eliminating the need to manually recreate vessel and exchanger equipment within your plant design software. Having trouble viewing this video? Download video (.mov 57MB)

Quickly Create 2D Drawings In Inventor

See how to use a COMPRESS (ASME Code compliant) 3D solid model to quickly create 2D pressure vessel drawings using Autodesk Inventor. Having trouble viewing this video? Download video (.mov 9MB)

3D Solid Model “Walk Through”

With the COMPRESS Solid Model designers can now "walk through" vessels to verify nozzle positions and projections. Having trouble viewing this video? Download video (.mov 13MB)

+1 (941) 927-2670 | sales@codeware.com