Codeware On-Demand Webinars & Tutorials

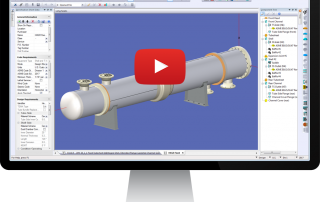

Advanced ASME Reports, Code Compliance, and Maintaining Nozzle Positions in COMPRESS

We're pleased to announce the release of COMPRESS 2020 Build 8000. New features include: Compliance with the 2019 Edition of the ASME Code Advanced Report Formatting for easier to read design reports Maintaining nozzle positions when adding or deleting components Please watch the video below to see these new features in action. Download [...]

ASME IX Code Compliance and Brazing Rules in Shopfloor

We're pleased to announce that Shopfloor 2020 has been released. Major new features include: Compliance with the 2019 Edition of ASME IX ASME IX brazing rules have been added AWS Forms Please watch the video below to see these new features in action. Download Video (.wmv 11MB) If you're not currently using Shopfloor, [...]

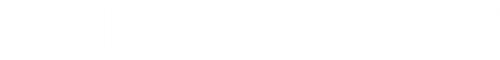

Quickly Generate Detailed FFS Reports With INSPECT

Do your current Fitness-For-Service (FFS) reports leave you wondering how the answers were calculated? Are you spending too much time creating FFS reports? INSPECT will save you time by producing audit ready reports with a single button click. In this video we show you how easy it is to create detailed API 579-1 documentation using INSPECT. Download Video (.wmv [...]

Nozzle Couplings and Slotted Anchor Bolt Holes in COMPRESS

We're pleased to announce the release of COMPRESS 2019 Build 7910. New features include: Additional nozzle coupling types An improved heat exchanger entry dialog Slotted saddle anchor bolt holes Please watch the video below to see these new features in action. Download Video (31 MB) If you're not currently using [...]

API 579-1 Part 9 Crack-like Flaw Assessments and Excel Integration in INSPECT

We're pleased to announce the release of INSPECT 2019 Build 7910. New feature additions include: Level 1 crack-like flaw assessments Support for ASME® Codes dating back to 1950 Import/Export Excel® inspection data files Drag and drop CML placement To see these new features in action watch the video below: Download Video (47 MB) [...]

Shopfloor – Generating Manufacturer’s Data Reports

Shopfloor features integration with COMPRESS. Pressure vessels and heat exchangers designed using COMPRESS can be imported directly into Shopfloor saving time and reducing errors. In addition to assigning WPS's and welders to the various joints, Shopfloor creates Manufacturers's Data Reports (U Forms). Download Video (50 MB) To see how Codeware's suite of products can benefit your organization [...]

Report Generation in COMPRESS

Are you tired of spending extra time producing a final calculation report? Did you know in COMPRESS a final report is simply a one click button? Stop wasting time copy and pasting various outputs to get one report. In this video we show you how you can quickly run a report and customize it to fit your needs. Download [...]

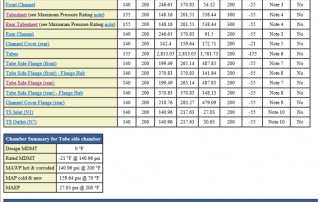

Design and Cost Vertical Heat Exchangers With COMPRESS

Designing Vertical Heat Exchangers With COMPRESS Is designing and estimating heat exchangers consuming a lot of your time? COMPRESS makes it easy to design and cost heat exchangers by including: COSTER for consistent and accurate quotations Consideration of API 660 nozzle loadings along with a WRC 107 and WRC 537 analysis Comprehensive ASME and TEMA design reports for [...]

Shopfloor Email Notifications

Shopfloor Email Notifications Email continuity alerts should be a standard feature of your welding software. If your current software provider charges extra for this or you're simply not satisfied with the service they provide it's time to explore the many benefits of Shopfloor. Shopfloor makes tracking welders easy with: Weld log updates for individual or multiple welders (Bulk Continuity) Email alerts for pending [...]

Defaults, Options & Preferences

Setting Shopfloor Defaults and Preferences Shopfloor helps you organize equipment (vessel) fabrication by associating it with a job (order) and assigning that job to a shop (location). In addition, a company in Shopfloor can have one or more shop locations. As explained in this tutorial, Shopfloor includes options for setting up user, shop and company-wide defaults. Download Video (7.8 [...]

Shopfloor – Maintaining Welder Continuity

Maintaining Welder Procedure Qualifications (WPQ) Shopfloor simplifies the task of creating and tracking WPQ forms and maintaining welder qualifications (continuity). Shopfloor's weld log tracks continuity and helps prevent welder expirations and costly re-qualifications. This tutorial video shows you how to set up a new welder and use Shopfloor's WPQ management tools. Download Video (66 MB)

Shopfloor Tutorial – Adding a New Welder

How to Add a New Welder in Shopfloor Shopfloor provides the ability to easily set up new employees and grant them the appropriate level of system access. Shopfloor's administrative access control permits users having "Employee Edit" access to modify access settings for any other user. Shopfloor also includes a special "Welder Access" setting which provides employees designated as welders with [...]

+1 (941) 927-2670 | sales@codeware.com