API 579-1 Part 14 Fatigue Assessments Using INSPECT

Fatigue is defined as a failure mechanism that involves cracking due to cyclic (or fluctuating) stress. Stresses may be either tensile, compressive or torsional. Cracking is typically caused by tensile mechanical stresses that are accompanied by another mechanism such as structural damage or corrosion. As mentioned in numerous references, it is worth noting that fatigue failures can happen at stresses below the yield strength of the material.

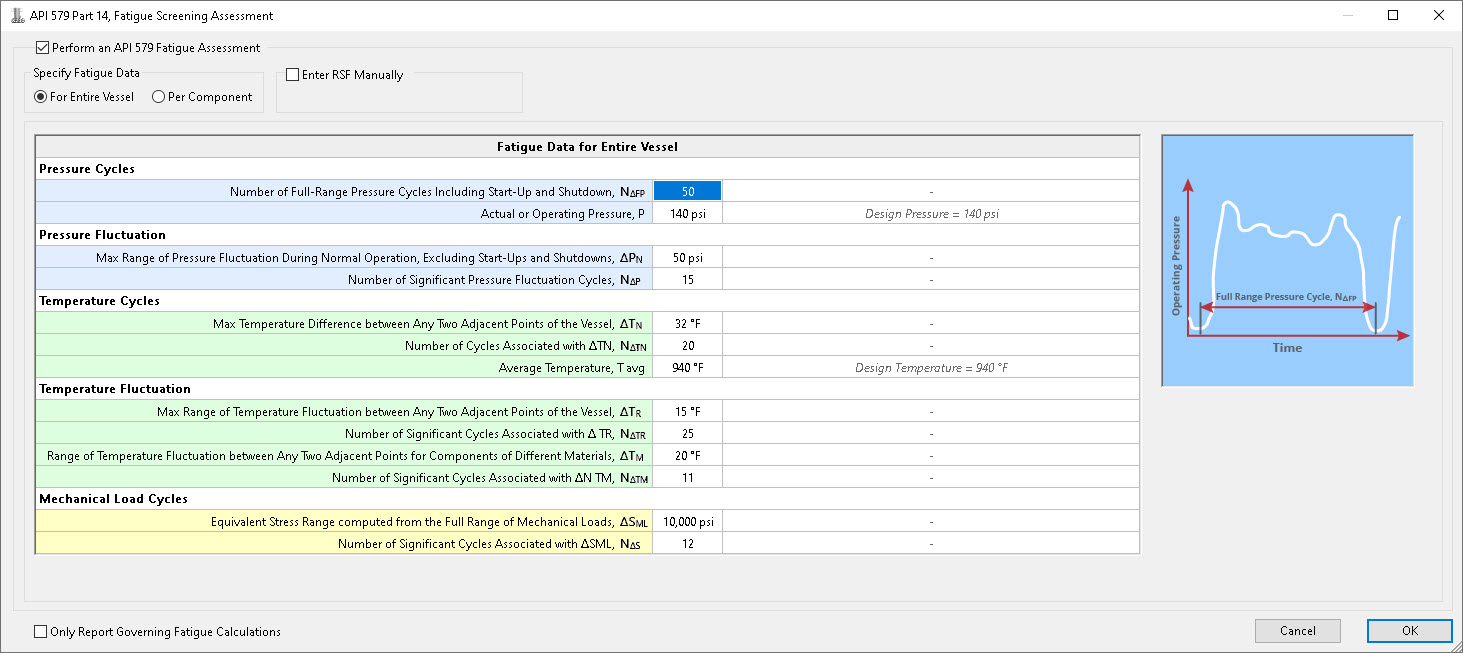

INSPECT includes support for performing API 579 Part 14 Fatigue Assessments. Its ability to quickly model complete vessels makes adding a Fatigue Assessment very simple. INSPECT’s fatigue assessment scans the vessel for other flaw types and allows the user to adjust the “remaining strength factor” (RSF) as required by API 579.

Images describing all cyclic load inputs are provided. This helps users determine which equipment histogram data to include in the assessment.

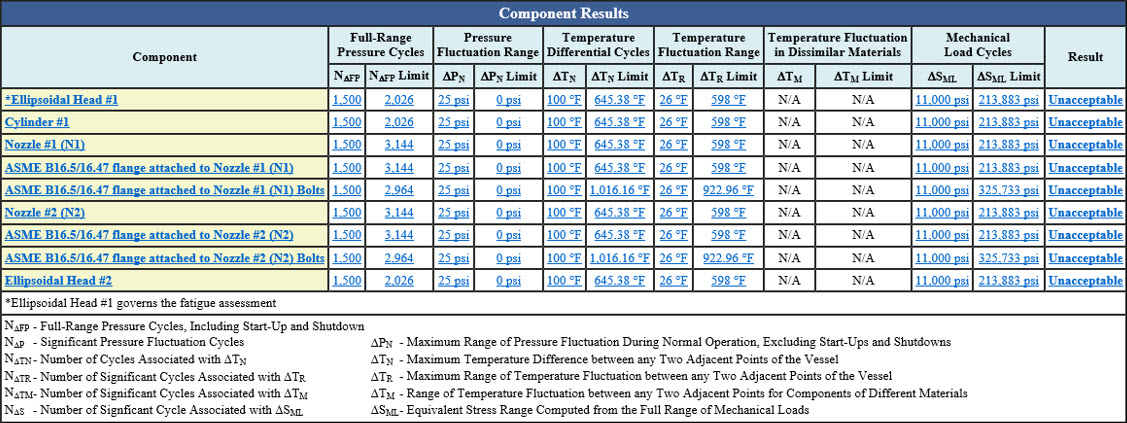

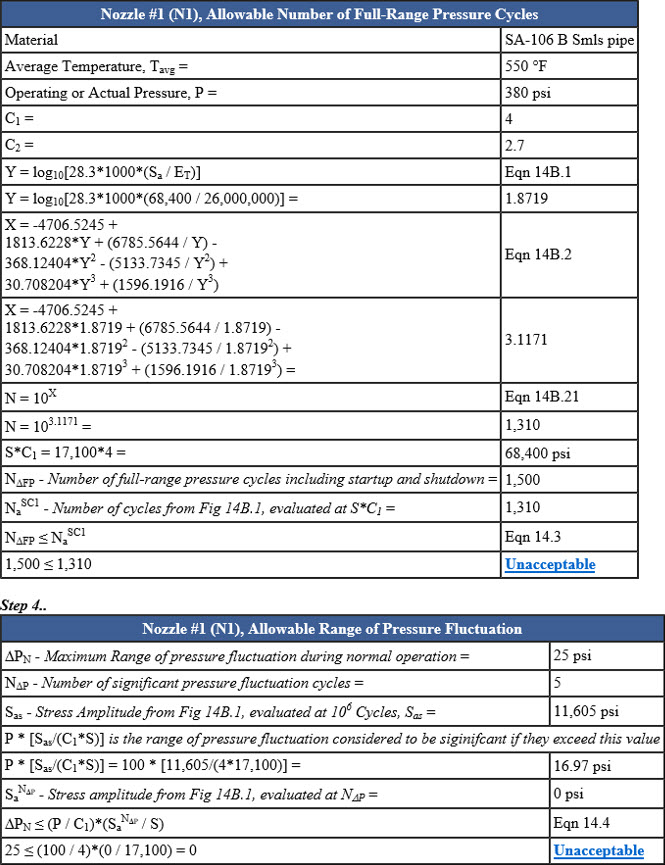

Detailed Fatigue Reports Are Provided

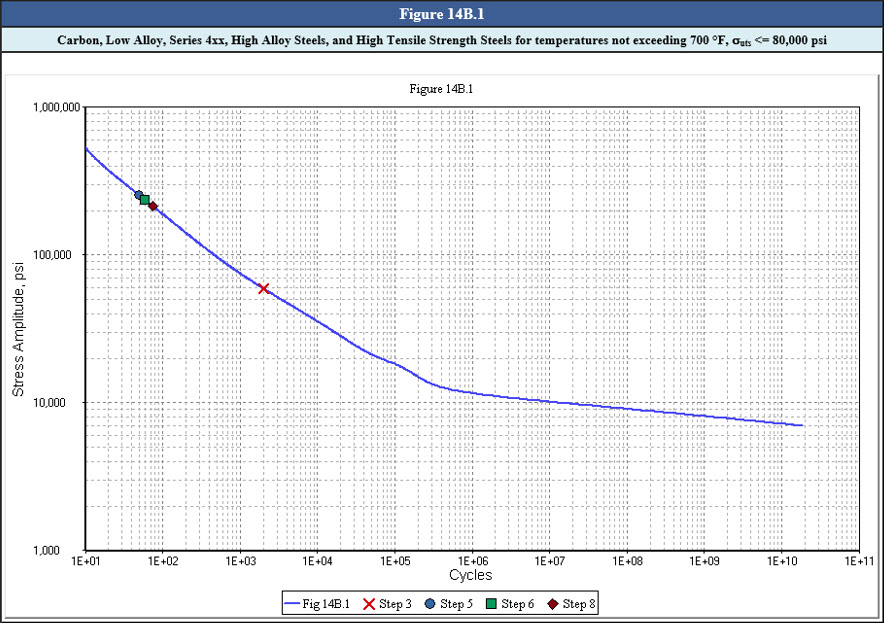

INSPECT creates detailed Fatigue Assessment reports for each component analyzed. Nozzles often govern the fatigue life of pressure vessels and INSPECT makes it easy to find the governing component. An example Part 14 nozzle report (right) and fatigue curve (below) are shown here.