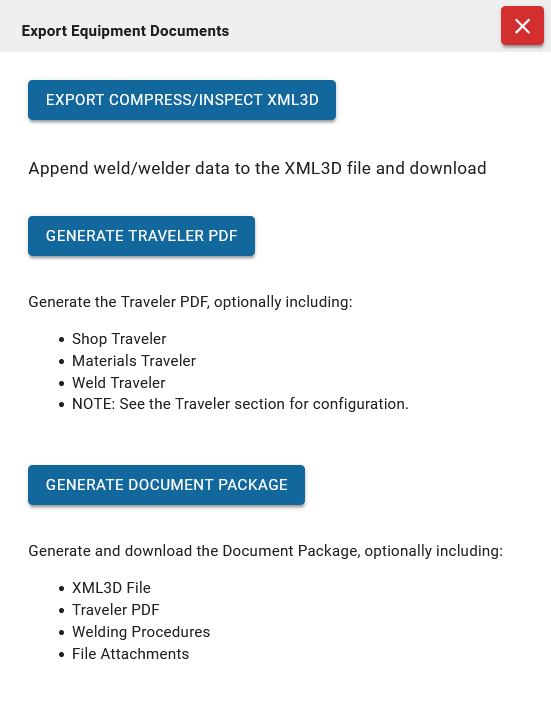

Working With Shop Travelers in Shopfloor

Working With Shop Travelers in Shopfloor

Shop Traveler documents are a vital component of any fabrication process. They layout a framework for ensuring equipment is consistently constructed to the highest quality standards. The traveler documents in Shopfloor provide a controlled and organized way to trace materials, track welding, and ensure that proper QA procedures are followed.

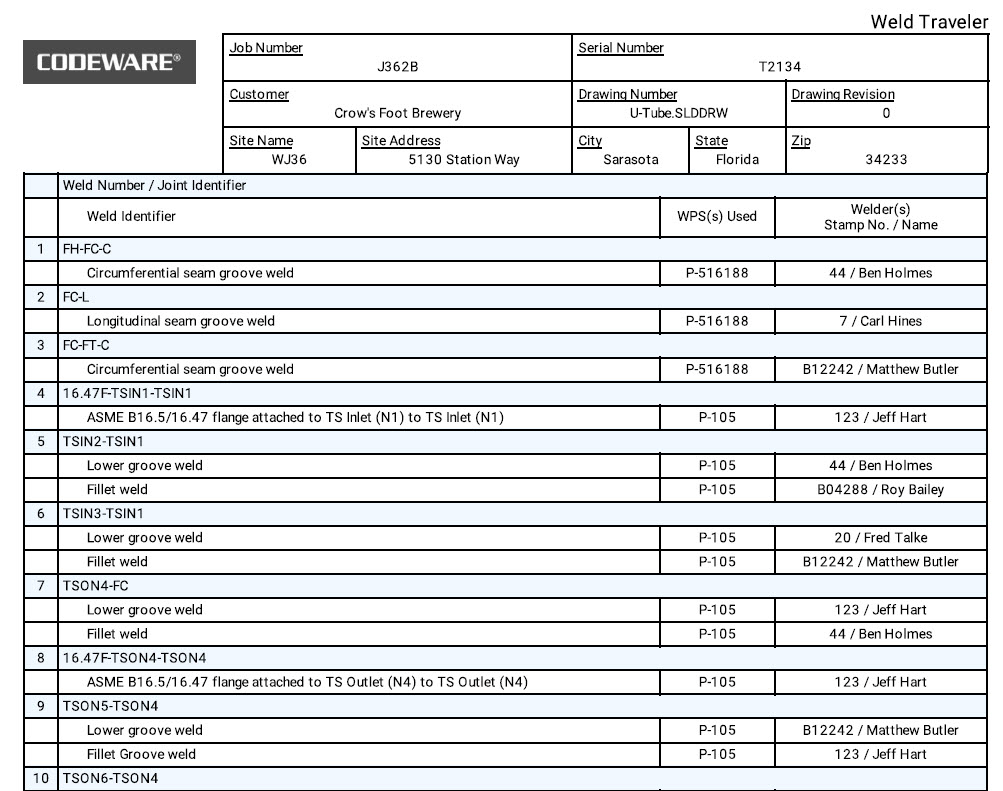

Shopfloor’s documentation includes three types of shop travelers that can be exported in pdf format. They address general work-in-progress, materials, and welds.

The Work-In-Progress Traveler in Shopfloor

The Work-In-Progress Traveler in Shopfloor

The Shop Traveler document provides a way to track the various tasks performed during fabrication. Tasks are user configurable and can include activities from initial design and drawings review through hydrotest sign-off. Inspection and hold points may also be defined as required.

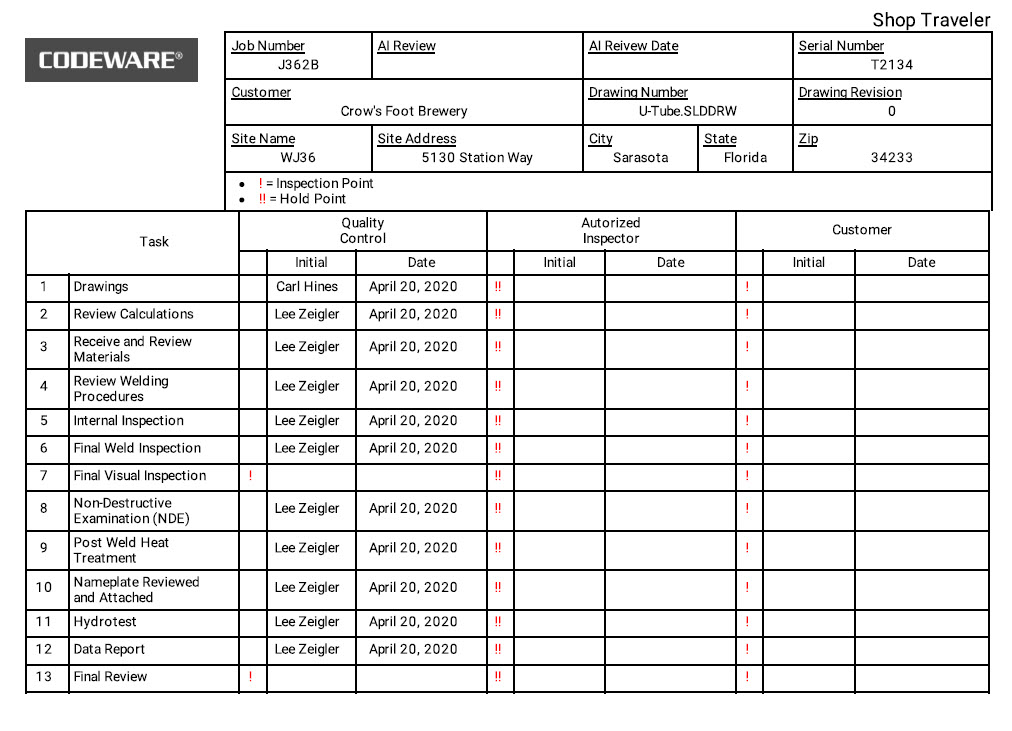

The Shopfloor Materials Traveler

The Shopfloor Materials Traveler

The Materials Traveler is used to show what material was used to make which specific part. It relates material heat and trace numbers back to individual vessel components like nozzles and shells.

Note that when Shopfloor is used with COMPRESS (or INSPECT), the components listed here match the component names specified in the COMPRESS design file.

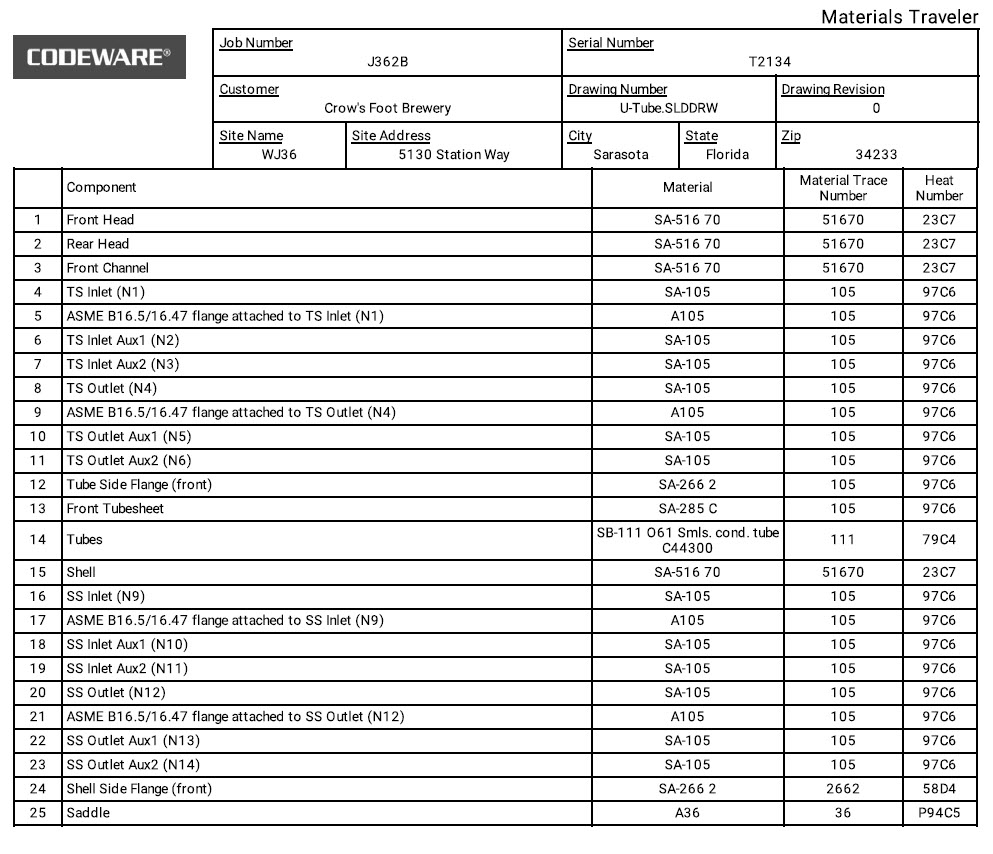

The Shopfloor Weld Traveler

The Shopfloor Weld Traveler

The Shopfloor Weld Traveler provides weld traceability by linking welding procedures and welders with physical welds on the heat exchanger or pressure vessel. It lists each weld along with its associated WPS number and welder identification.

When Shopfloor is used with COMPRESS and the Codeware Interface (CWI), the welds listed here match the welds shown on CWI generated weld maps and drawings.