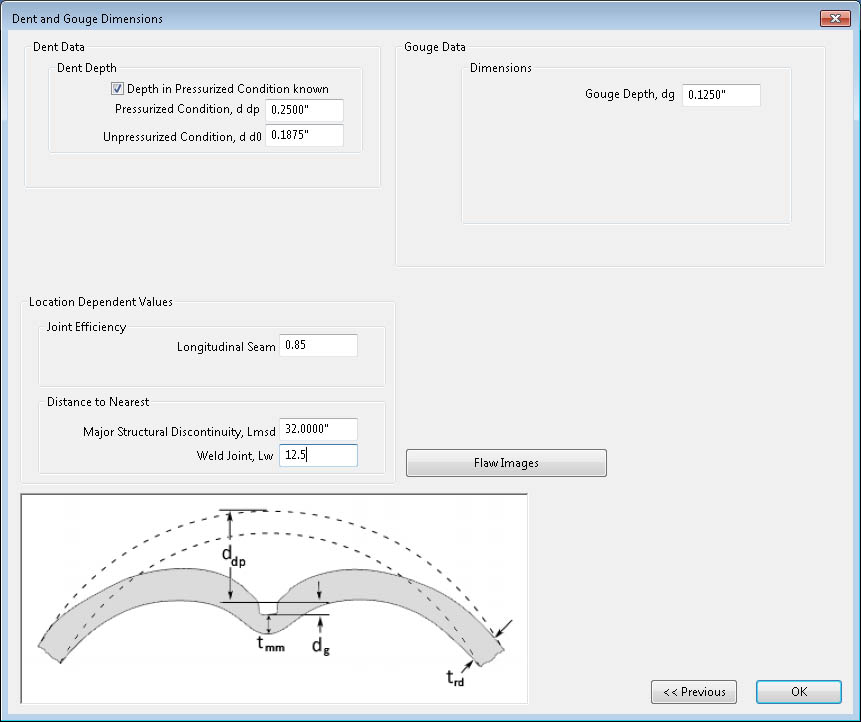

Part 12 – Dents, Gouges & Dent-Gouge Combinations

INSPECT performs Part 12 assessments and generates detailed API 579 reports with a single button click. Level 1 and 2 dent, gouge and dent-gouge combinations are available. Dents and dent-gouge combinations may be placed on carbon steel cylindrical shells and pipe segments. Gouges may be placed on cylindrical shells and pipe segments constructed from any material. Other features include:

Brittle fracture analysis per Part 3 that may be individually specified for each Part 12 flaw.

Dent and gouge flaws displayed to scale on the INSPECT 3D model.

An option to consider dents in cyclic service.

The ability to store Part 12 flaw images, as many as may be required.

INSPECT Featured Capabilities